When you pick up a prescription for a generic drug, you’re probably saving 70% or more compared to the brand-name version. But why? It’s not because generics are lower quality. It’s because their manufacturing cost analysis reveals a completely different business model-one built on efficiency, scale, and avoiding the massive upfront expenses that branded drugmakers carry.

They Don’t Pay for Research and Development

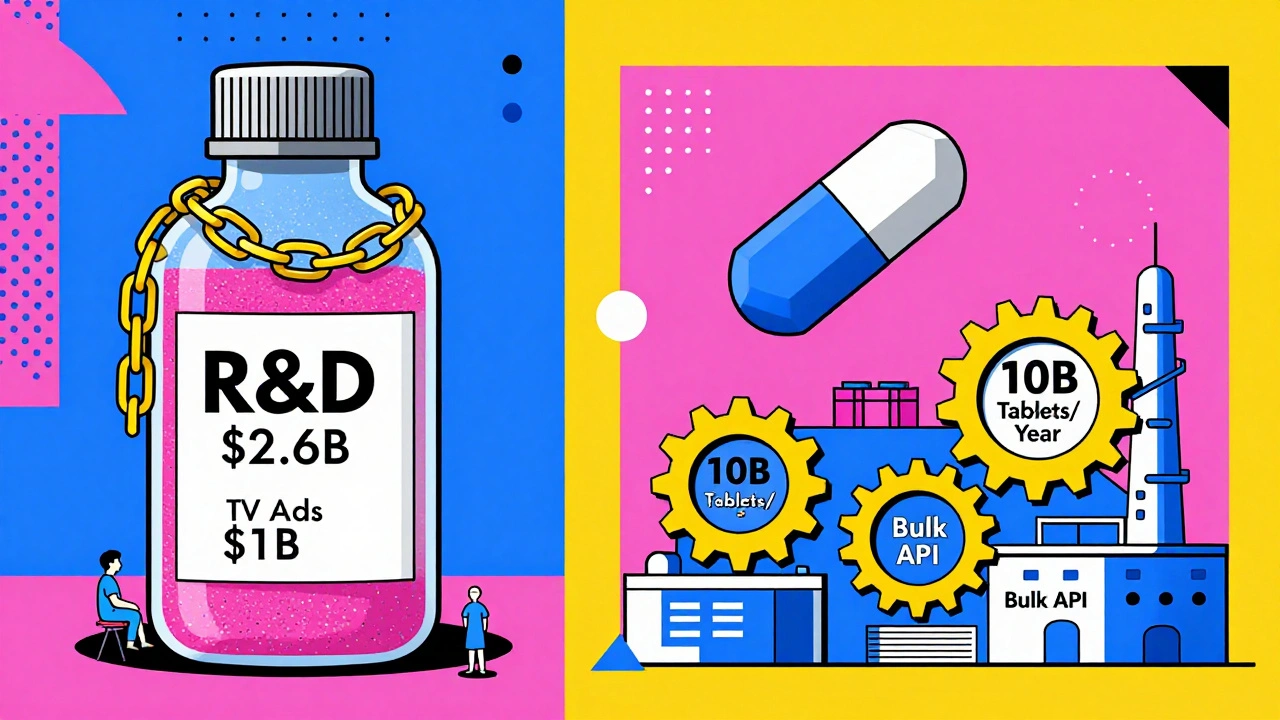

Branded drugs take over a decade and $2.6 billion on average to develop. That’s not just lab work. It’s clinical trials with thousands of patients, years of regulatory back-and-forth, and failed candidates that never made it to market. All of that gets baked into the price. Generic manufacturers don’t do any of that. Once a brand-name drug’s patent expires, they only need to prove their version is bioequivalent-meaning it works the same way in the body. That process costs between $2 million and $5 million, and takes about three years. That’s less than 0.2% of what the original drugmaker spent.Production Volume Drives Costs Down-Fast

The more you make of the same pill, the cheaper each one becomes. Generic manufacturers produce billions of units of the same drug. For every time production volume doubles, the cost per unit drops by 18%. For drugs made in large batches-like statins or blood pressure meds-that number can jump to 45% savings per doubling. That’s not magic. It’s physics. Machines run longer. Labor gets more efficient. Raw materials are bought in bulk at discount prices. A single production line making 10 billion tablets a year doesn’t cost twice as much as one making 5 billion. It costs far less.Who Pays for Marketing? No One

Branded drugs spend billions on TV ads, doctor visits, and sales reps. A single drug like Humira might cost more on marketing than it does on manufacturing. Generic companies? They rarely advertise directly to patients. Their customers are pharmacies and insurers. Their sales team is small. Their marketing budget? Barely a footnote. That’s another 20-30% off the price tag before you even get to the pill.

Cost Breakdown: What’s Actually in a Generic Pill?

Let’s break down what goes into making a generic drug:- Active Pharmaceutical Ingredient (API): This is the actual medicine. It makes up the biggest chunk of cost-sometimes 50% or more. Prices for APIs can swing 20-30% a year based on where the raw materials come from (China, India, Europe). A shortage in one chemical can spike costs overnight.

- Excipients: These are the fillers, binders, and coatings. Think of them as the bread and butter of the pill. They’re cheap, standardized, and bought in massive quantities.

- Quality Control: Every batch must pass strict tests. This isn’t optional. But generic manufacturers use the same FDA-approved methods as branded companies. The difference? They don’t have to invent them. They just follow the playbook.

- Packaging: Bottles, labels, blister packs. Simple, repetitive, automated. A machine can pack 10,000 pills an hour. No human needed.

Put it all together, and the total cost to produce a single generic tablet can be as low as a few cents. That’s why a 30-day supply of generic lisinopril costs $4 at Walmart, while the brand version might be $150.

Competition Crushes Prices

When only one or two companies make a generic, prices stay high. But when five or six enter the market? Prices collapse. The FDA found that when six or more generic makers produce the same drug, prices drop over 95% compared to the original brand. That’s not just competition-it’s a price war. And the winner? The patient.Take cetirizine, the generic for Zyrtec. When only one generic was available, it cost 41% less than the brand. When six generics hit the market? The price dropped to 96% less. That’s not inflation. That’s market force.

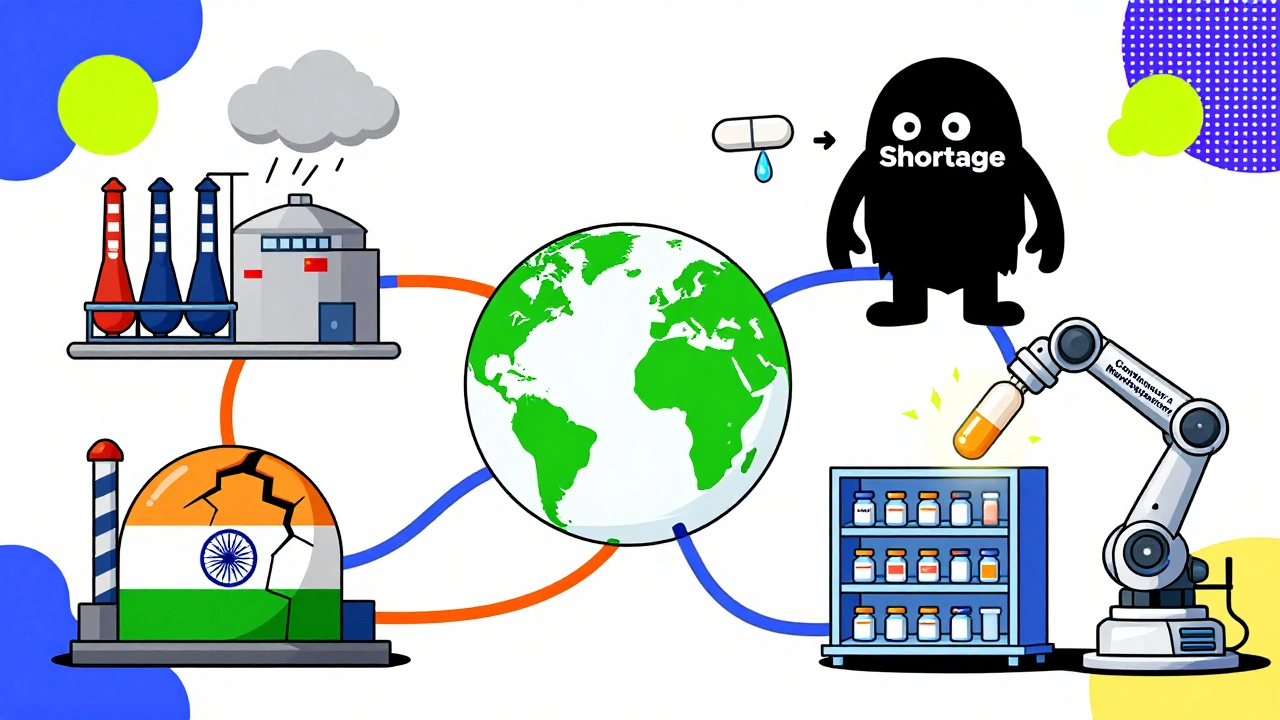

Scale Has Limits-And Risks

There’s a catch. Generic manufacturers don’t just need volume-they need the right volume. BCG’s research found that once a company makes more than 30-40 billion oral tablets a year, costs start creeping back up. Why? Logistics get messy. Supply chains stretch too thin. Quality control becomes harder. That’s why most generic makers focus on a few high-volume drugs rather than trying to make everything.And here’s the darker side: when margins are razor-thin, even a small disruption can cause shortages. In 2022, there were 350 active drug shortages in the U.S.-many of them generics. Why? A factory in India had a quality issue. A chemical supplier in China shut down. A hurricane hit a packaging plant. With no profit cushion, there’s no room to absorb these shocks. That’s why experts warn that the system is fragile, even if it’s cheap.

Why Do Brands Still Make Money?

You’d think generics would take over everything. But they don’t. In the U.S., generics fill 90% of prescriptions-but only account for 15.8% of total drug spending. Why? Because the most expensive drugs aren’t generics. Cancer treatments, rare disease meds, and new biologics still carry six-figure price tags. Generics dominate the common stuff: blood pressure pills, antidepressants, antibiotics. That’s where the real savings happen.And here’s the twist: sometimes the same company that makes the brand drug also makes the generic. They sell the brand at $100 a pill and the generic at $2. The profit margin on the generic? Sometimes less than 10%. But they make up for it in volume. And they keep the brand priced high for those who still pay full price.

What’s Changing? Automation and Regulation

The next big shift? Automation. Companies are investing in continuous manufacturing-machines that turn raw powder into finished pills in hours, not days. This cuts waste, reduces labor, and improves consistency. By 2027, experts predict automation will cut generic production costs by another 20-25%.The FDA is also speeding things up. Their new GDUFA III program is pushing approval times down from 40 months to 24. That means more generics hit the market faster, which means more price pressure. Meanwhile, Medicare’s new ability to negotiate drug prices could push generic prices down another 10-15%.

But there’s a risk. If too many manufacturers leave the market because they can’t compete, competition drops-and prices rise again. That’s why regulators are watching consolidation closely. If Teva and Sandoz control half the market, who’s left to keep prices low?

The Big Picture: Savings That Add Up

From 2023 to 2027, generic drugs are projected to save the U.S. healthcare system $1.7 trillion. That’s not a guess. That’s based on actual prescription volume and price data. It’s the difference between a patient skipping their blood pressure meds because they can’t afford them-and taking them every day.Generics aren’t just cheaper. They’re essential. They make healthcare work for millions of people who can’t pay $500 for a month’s supply of insulin. They let insurers keep premiums lower. They let governments stretch budgets further.

The cost advantage isn’t luck. It’s design. It’s scale. It’s a system built to cut out waste-not quality. And as long as competition stays fierce, that system will keep working.

December 3, 2025 AT 12:48 PM

so like… generic pills are basically just brand names with a bad haircut and no ads?? 😅 i mean i get it but also… why does my heart medication taste like chalk now??

December 4, 2025 AT 03:57 AM

it’s wild to think that the same molecule that saves lives is priced like a luxury good just because someone spent a decade proving it works… and then someone else makes it cheaper and gets called ‘low quality’. we’re not punishing innovation-we’re punishing access.

kinda sad when you think about it.

December 5, 2025 AT 08:51 AM

my grandma takes 7 generic meds and she swears they work better than the brand ones-says the brand ones made her dizzy. i always thought it was placebo but now i’m wondering if the fillers are just different.

also-walmart’s $4 lisinopril saved her life. literally.

December 6, 2025 AT 23:55 PM

ohhhhh so THAT’S why the pharmaceutical industry hates generics?? not because they’re unsafe-because they’re TOO efficient??

like… imagine if you spent 10 years and $2.6 BILLION building a car… and then someone else just copies the engine and sells it for $2000.

you’d cry. you’d lobby. you’d buy a senator. you’d call it ‘unfair competition’.

but it’s not unfair-it’s capitalism working. the system’s rigged to protect the guy who invented the wheel… not the guy who figured out how to mass-produce it.

and now we’re getting mad when the wheel gets cheaper??

also-did you know some of these ‘generic’ manufacturers are owned by the same companies that make the brand? they’re just playing both sides. genius. pure genius.

December 7, 2025 AT 19:42 PM

the part about marketing being more expensive than manufacturing is insane

like why are we paying for that

December 8, 2025 AT 23:05 PM

you know what’s even crazier? the fact that we don’t treat medicine like a public utility.

we don’t charge people extra for clean water because they can’t afford it. why is a lifesaving pill any different?

and honestly? if we had universal pricing like other countries, we wouldn’t need this whole ‘generic vs brand’ drama.

but hey-maybe we’re just too proud to admit we need a better system.

December 9, 2025 AT 10:37 AM

while the cost savings are undeniable, we must also acknowledge the systemic fragility introduced by extreme thin margins.

the supply chain dependencies on geopolitical regions with volatile regulatory environments create a latent risk that could cascade across public health infrastructure.

in other words: cheap is great-until it’s not there anymore.

December 9, 2025 AT 23:42 PM

in india we make most of the api for usa generics… but last year factory closed because of pollution fine… then 3 month shortage of metformin… everyone panic buying.

so yes cheap but also very fragile

December 10, 2025 AT 19:32 PM

the real win here isn’t the price-it’s the fact that millions of people who would otherwise skip doses or go without now have consistent access.

that’s not just economics. that’s public health. that’s dignity.

December 11, 2025 AT 05:07 AM

so let me get this straight… we’ve built an entire healthcare system where the only way to afford medicine is to rely on a supply chain run by sweatshops in India and China, with zero profit margin, and if one factory sneezes, half the country can’t get their blood pressure pills?

brilliant.

truly the pinnacle of american innovation.

also-someone tell me why we don’t just nationalize the API production? we can build nukes. why can’t we build pills?

December 12, 2025 AT 18:59 PM

when i was in hospital last year, they gave me generic metoprolol… i cried because i thought it was fake… then i checked the bottle and realized-oh. it’s just… cheaper.

and it worked.

same pill. different price tag. same life saved.

December 14, 2025 AT 13:26 PM

you know what’s worse than the shortages?

the fact that the same companies that make the generics also own the brands… and they *want* the shortages.

because when there’s a shortage, the price of the brand version goes up again.

and guess what? the insurance companies still pay for the brand.

so they profit from chaos.

it’s not capitalism.

it’s a scam with a pharmacy label.